bigbear1963

New CEG'er

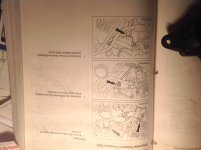

I recently purchased a 99 SVT #6787, and I am going through the mechanics, trying to undo some of the "mods". One discovery I made, while replacing the EGR valve this past weekend was an open air/vacuum lead on the manifold to EGR valve pipe. I am attaching a pic, even though it is very cramped back there. Any ideas where that lead should be connected? There is another twin lead nearby, also open, that leads somewhere in the engine. Does anyone know of a diagram of the EGR system which could shed light on this mystery?