cclngthr

CEG'er

1998 Contour: V6 automatic power everything

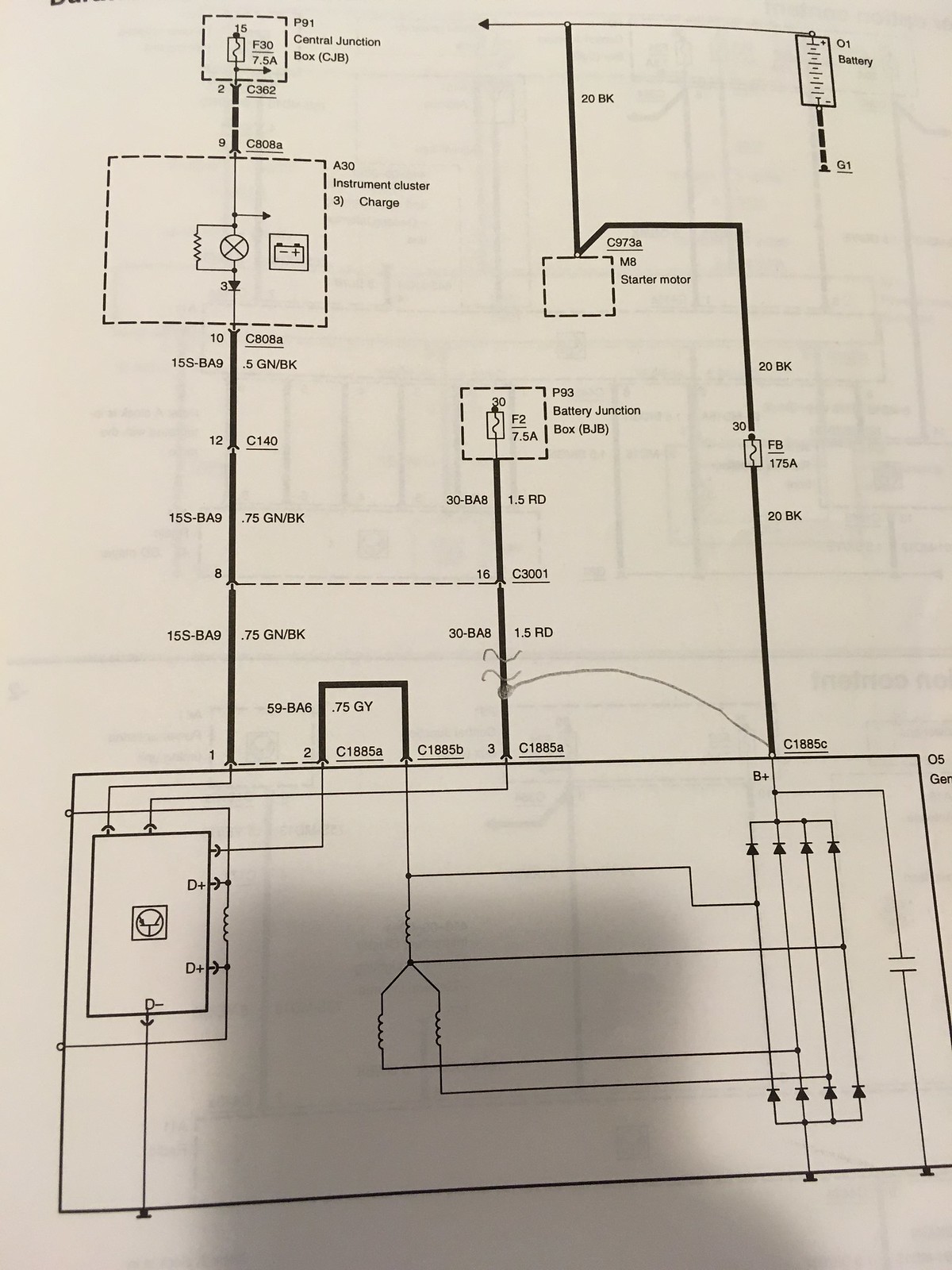

Alt crapped out last month when ATF from transmission sprayed everywhere. Replaced trans, alt and PS pump belts and tensioners. First alt replaced (shop is doing the work under warranty) had bad bearings/windings. It was charging somewhat but not enough. Brand was Ultima (reman/new) from O'Reilly. Shop went through 2 others that appeared to test ok on the bench, but only put out 12 volts on the car.

We also replaced the battery cables with slightly larger ones, better ground cables as well. However on the 4 power leads from the junction boxes were bundled together when they redid the wiring; and now the alt isn't charging. I find it odd that 3 alternators are not working in a series like this.

What I am wondering is if the bundled wires feeding power to the junction boxes may be part of the problem where the amperage is dropping just enough to not send the signals to the alternator to excite the rectifier in the alt. Is it possible that there could be resistance in that harness somehow (I don't see any wiring damage to indicate that. Also, I only see the red wires, not the white with black tracer wire.

Edit:

Did find the problem. In the instrument cluster, there is a communication bus line from the PCM and that monitors what is going on with the powertrain, airbag system, charging system and ABS (if that is installed). On the charging system, the cluster sends data back to the PCM on status of the charge and if it does not see it, the computer will either send data to the alternator to ramp up the charge; or turn it off. What it was doing is ramping up the alternator to full field 100% of the time. That shorted out the alternators immediately. On the oem alt, it did not short it out because the VR was able to handle that.

Alt crapped out last month when ATF from transmission sprayed everywhere. Replaced trans, alt and PS pump belts and tensioners. First alt replaced (shop is doing the work under warranty) had bad bearings/windings. It was charging somewhat but not enough. Brand was Ultima (reman/new) from O'Reilly. Shop went through 2 others that appeared to test ok on the bench, but only put out 12 volts on the car.

We also replaced the battery cables with slightly larger ones, better ground cables as well. However on the 4 power leads from the junction boxes were bundled together when they redid the wiring; and now the alt isn't charging. I find it odd that 3 alternators are not working in a series like this.

What I am wondering is if the bundled wires feeding power to the junction boxes may be part of the problem where the amperage is dropping just enough to not send the signals to the alternator to excite the rectifier in the alt. Is it possible that there could be resistance in that harness somehow (I don't see any wiring damage to indicate that. Also, I only see the red wires, not the white with black tracer wire.

Edit:

Did find the problem. In the instrument cluster, there is a communication bus line from the PCM and that monitors what is going on with the powertrain, airbag system, charging system and ABS (if that is installed). On the charging system, the cluster sends data back to the PCM on status of the charge and if it does not see it, the computer will either send data to the alternator to ramp up the charge; or turn it off. What it was doing is ramping up the alternator to full field 100% of the time. That shorted out the alternators immediately. On the oem alt, it did not short it out because the VR was able to handle that.