rkneeshaw

CEG'er

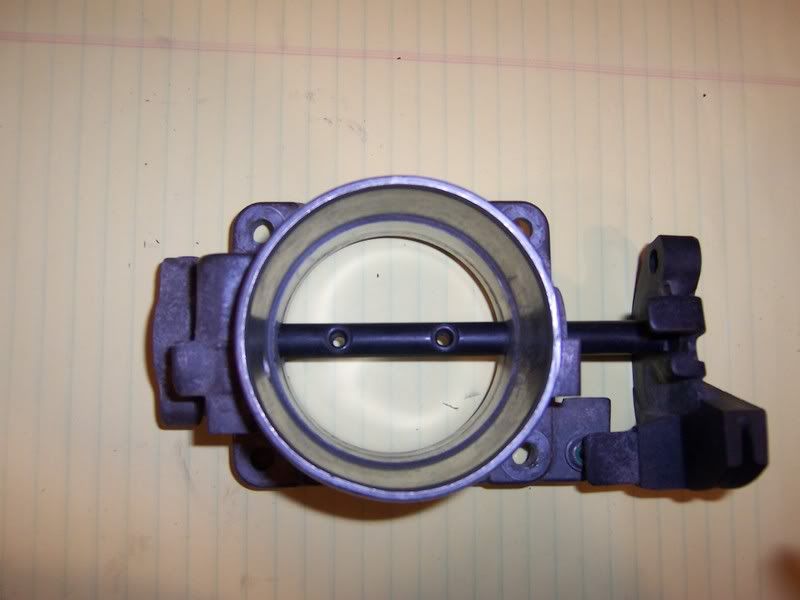

I've searched and heard of about 18 different ways to install a 65mm TB and I'm wondering if someone can give me a straight up, here's-the-best-way, buy-this answer. Please correct me where I'm wrong:

I've got a 3L with SVT UIM, so I think the UIM opening is 65mm which means it will bolt up to a 65mm TB quite well.

The SVT TB-to-UIM gasket I have seems like it is smaller than 65mm, closer to 62mm, so maybe I should be getting a mustang TB gasket? Whats the easiest solution here? I have to buy a new gasket anyway.... so if one works without modification I'll just order the right one.....

Is there a specific model year mustang TB I want? Seems there was mention of differences between different 4.6L mustang TB's.

And also, I'm under the impression that I can take a 65mm TB, and use the TPS, shaft, spring/linkage from my SVT TB and move it to the 65mm TB. Basically, use all the 60mm SVT parts except for the housing and butterfly plate, which I would use from the 65mm TB. (obviously I'd have to modify the SVT TB shaft to fit the larger butterfly, but that would be the only real "modifcation" other than swapping parts) Is this the best way to make this work?

And lastly, any odd side effects of this mod? Weird throttle response or anything?

I've got a 3L with SVT UIM, so I think the UIM opening is 65mm which means it will bolt up to a 65mm TB quite well.

The SVT TB-to-UIM gasket I have seems like it is smaller than 65mm, closer to 62mm, so maybe I should be getting a mustang TB gasket? Whats the easiest solution here? I have to buy a new gasket anyway.... so if one works without modification I'll just order the right one.....

Is there a specific model year mustang TB I want? Seems there was mention of differences between different 4.6L mustang TB's.

And also, I'm under the impression that I can take a 65mm TB, and use the TPS, shaft, spring/linkage from my SVT TB and move it to the 65mm TB. Basically, use all the 60mm SVT parts except for the housing and butterfly plate, which I would use from the 65mm TB. (obviously I'd have to modify the SVT TB shaft to fit the larger butterfly, but that would be the only real "modifcation" other than swapping parts) Is this the best way to make this work?

And lastly, any odd side effects of this mod? Weird throttle response or anything?