SkullV

Veteran CEG'er

I built one of these a while ago but it was all solid mounted and getting old. Between the rev hang, rough idle, and vacuum leak sounds on my car I figured I would just build another one and document the process in case anyone else is interested.

Parts:

Pretty simple stuff and works great when all hooked up. This weekend I'll take some demonstration photos and show how to use it on the car to actually detect leaks.

Build/use at your own risk. I assume no liability relating to the building/use of this machine.

Parts:

- 1g Paint Can

- 3x 3/8" x 1/4" Hex Bushing

- 1x 1/4" x 1/4" MPT Nipple

- 1/4" Airline Ball Valve

- 1/4" Airline Connector

- Weller Soldering Iron

- JB Weld

- Drill

- Drill Bits

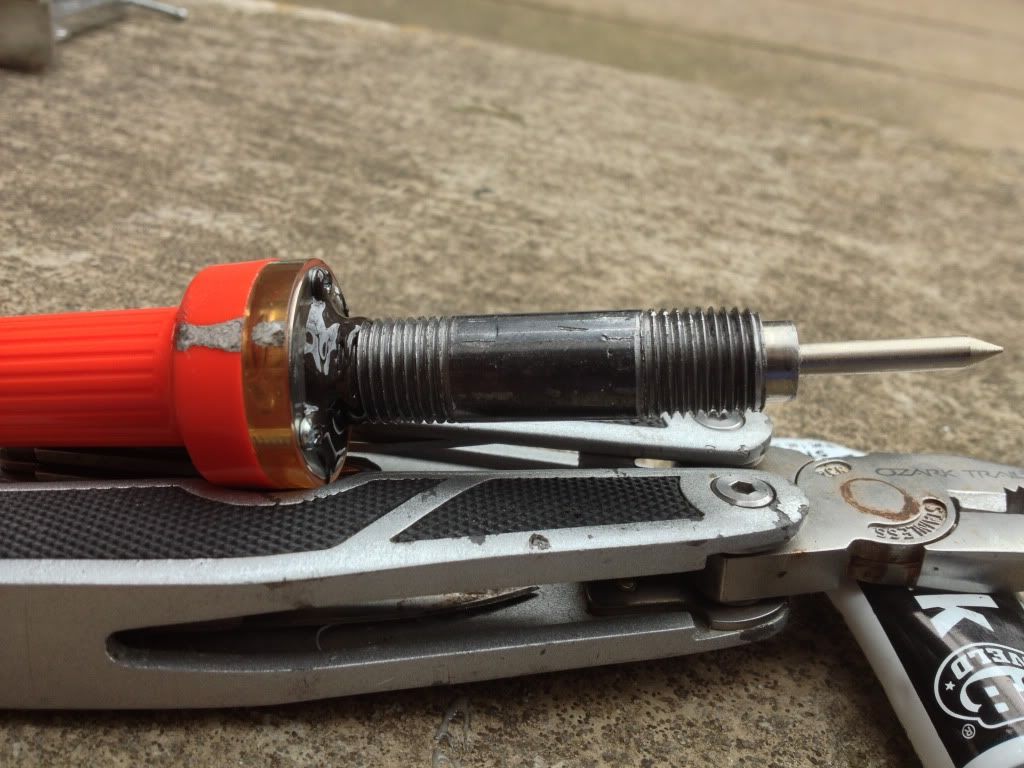

Drill out the nipple so it will slide completely over the soldering iron's metal shaft:

Drill two ~5/8" holes on opposite sides of the paint lid"

Drill one ~5/8" hole on the side of the paint can near the bottom (high enough so that the hex bushing will not sit on the edge of the can):

JBweld the 1/4" nipple onto the soldering iron shaft near the bottom of the shaft. It is very important to get a good seal here! Apply a second coat if necessary after the first coat cures.

JBweld each of the Hex Bushings into place, allow JBweld to cure, apply another coat of JBweld if necessary to seal. Once fully cured, thread in your soldering iron and your airline connectors. Use teflon paste/tape on all joints to ensure a proper seal:

Pretty simple stuff and works great when all hooked up. This weekend I'll take some demonstration photos and show how to use it on the car to actually detect leaks.

Build/use at your own risk. I assume no liability relating to the building/use of this machine.