B3NN3TT

Hard-core CEG'er

So I finally have this thing back together now, from the Torsen swap. MAN, what a horrible job, pulling the transaxle. I had one large bolt left over when I was finished - and I have NO CLUE where it came from. But everything seems fine - so I must be OK for now!

Here's a few photos...

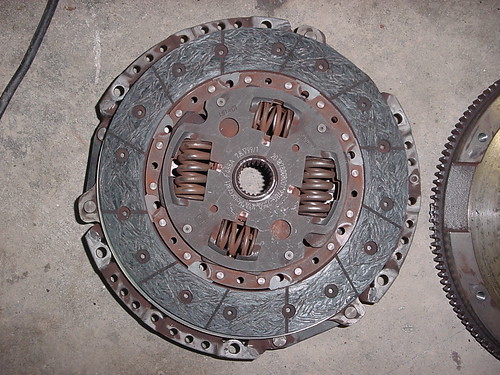

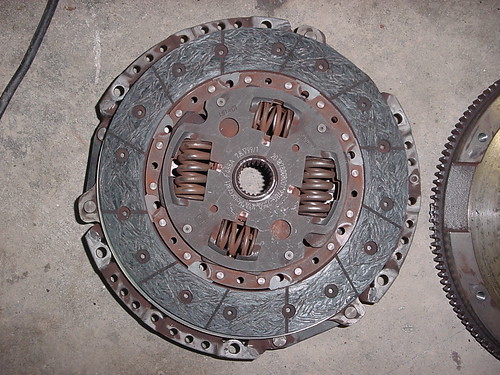

Some parts pr0n - SVT clutch, Fidanza flywheel, and Torsen LSD

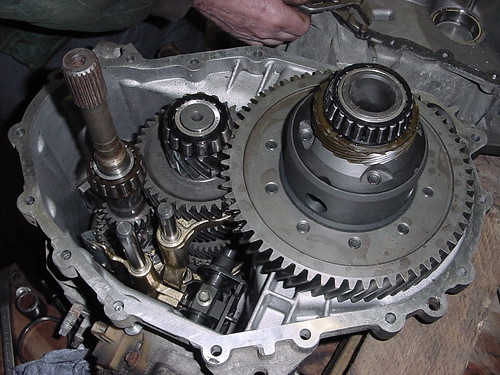

No transmission!

Stock clutch disc - doesn't look bad at all, especially for 135,000 miles all-original!

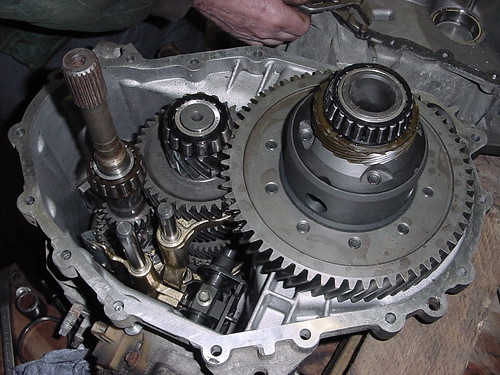

Stock differential looks a little weird...

Yeah. Definitely something wrong here.

The transaxle magnet - with a lot of my old diff stuck to it:

MUCH better.

I'm still on break-in for the new clutch, so I've not really hammered on it at all yet (although I did open it up some today at 460 miles - feels great!). While it was down, I installed a new water pump and thermostat, and a weapon-R y-pipe. Should feel like a new car when the break-in period is over - around lunchtime tomorrow!

Here's a few photos...

Some parts pr0n - SVT clutch, Fidanza flywheel, and Torsen LSD

No transmission!

Stock clutch disc - doesn't look bad at all, especially for 135,000 miles all-original!

Stock differential looks a little weird...

Yeah. Definitely something wrong here.

The transaxle magnet - with a lot of my old diff stuck to it:

MUCH better.

I'm still on break-in for the new clutch, so I've not really hammered on it at all yet (although I did open it up some today at 460 miles - feels great!). While it was down, I installed a new water pump and thermostat, and a weapon-R y-pipe. Should feel like a new car when the break-in period is over - around lunchtime tomorrow!

Last edited: