Big Jim

Hard-core CEG'er

Quit guessing. Read the seal.

I just weny out & found the pulley part & I'm uploading a pic of it.and on a seperate note...

Can someone, anyone, please post an actual picture of where the bolt for the damper begins? I don't want to cut the head of the bolt off and have more problems. I've been hacking on the cone part just in front of the damper and have not made any progress it seems. The only thing that is gone now is the actual pulley itself thanks the saw.

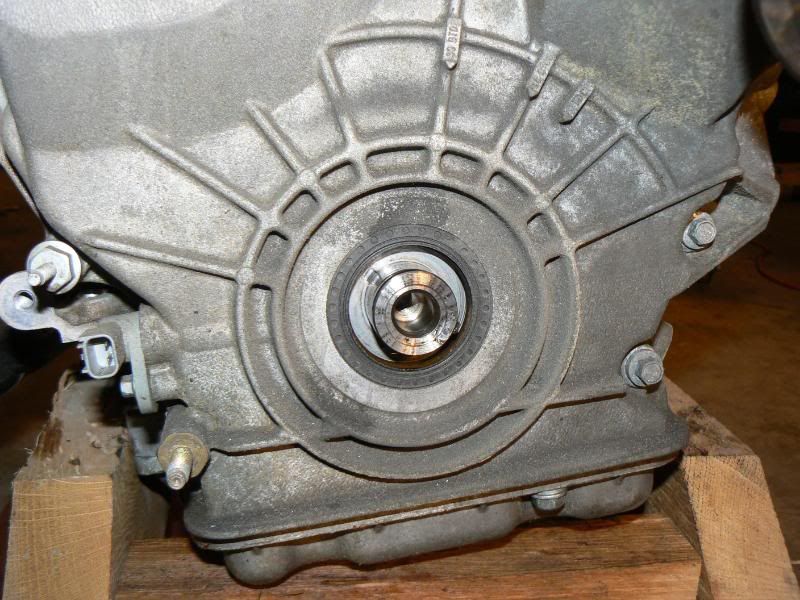

Don't forget on the other end of the crank there is a bushing that needs to be cut off so that the transmission shaft won't bind against it.