jolly8286

Hard-core CEG'er

He has a carbon fiber roof.

looking good! I notice the roof line was taped off. Is there a two tone skeem or did i miss that mentioned somewhere?

ya ya ya, thats all good and stuff but when are you getting back to posting about the motor

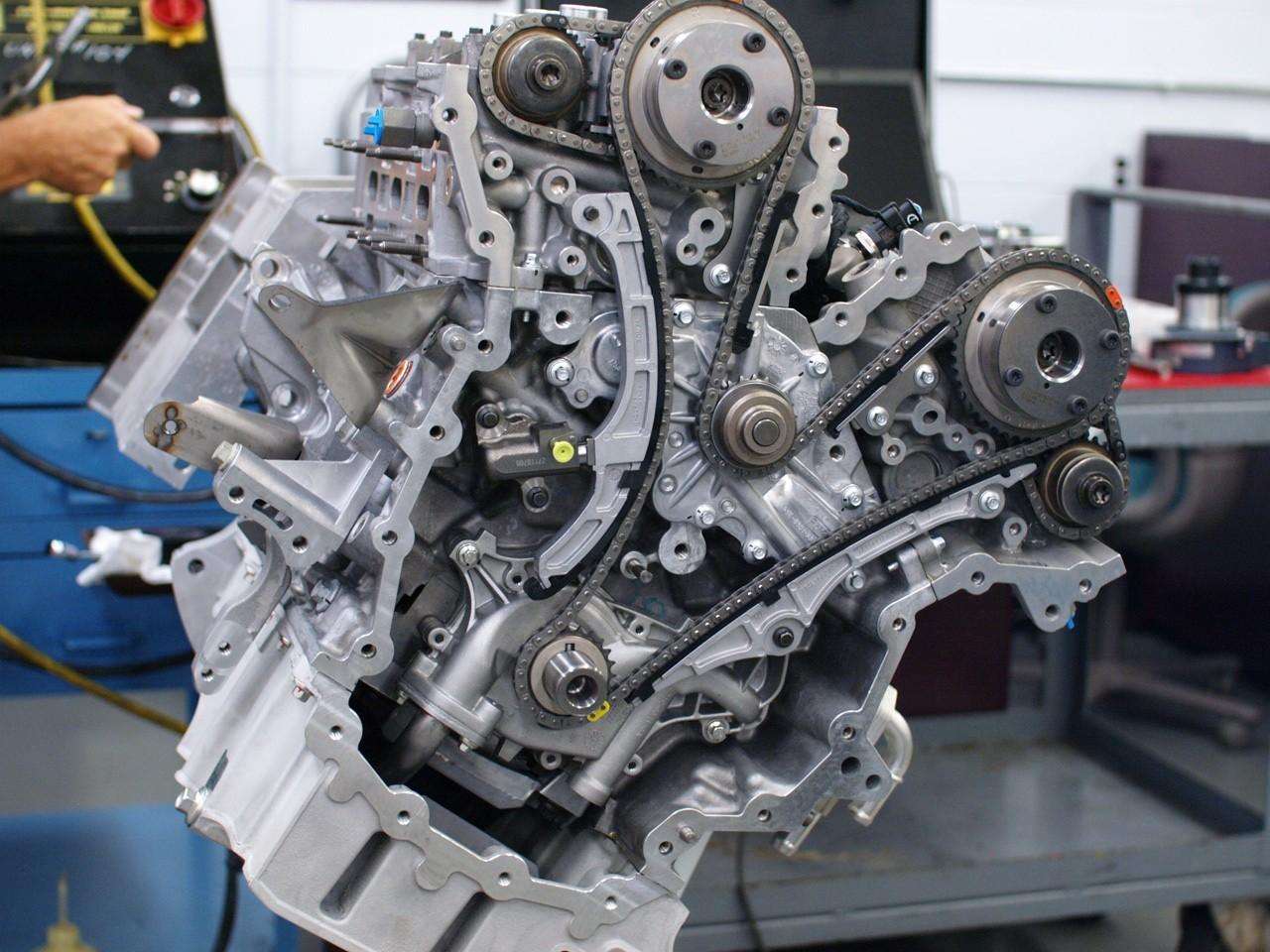

could always ask what the nobels are using for an oil pump. iirc they have the oil squirters also. It has been said before the the 3L duratec oil pump from an engine with VVT would be an upgrade also, iirc.

There is not alot of room to mount a dry sump tank with a turbo. Where do you think the tank would fit? My guess is you will have to fabricate a tank that is form fitted to the useable space.

The good news is a dry sump can act like a vacuum pump also, which on my race engine is good for 40 HP. It will help to eliminate any oil leaks.

My thought is right now to relocate the washer fluid bottle to where the battery used to be. I'd cut a hole in the inner fender for the washer bottle spout and then mount the bottle underneath. I would then re-route the lines from the driver side for the sprayers. Then I would mount an oil tank where the washer bottle used to be on the passenger side.

Ugh... well they are charging $1800 for the dry sump kit, then I would still need to fabricate the tank. This may be more then I care to spend.

Ugh... well they are charging $1800 for the dry sump kit, then I would still need to fabricate the tank. This may be more then I care to spend.

The man building the car with no limits has reached a limit? Lol, in all seriousness, that is incredibly expensive, not sure the advantages are worth the money, even on this car.

Well, I WAS thinking about it. F that S.

How about NOOOOOOOOOOOOO.

Cant you just run an accusump for like $300? Or does that not do the same thing?

I'm currently working with Terry Haines on my transmission. Another reason why I haven't started reassembling the powertrain. I'm looking into the possibility of having the gears coated/baked with a cermaic/moly coating. This would provide a little more of a cushion to the torque that is going to be flowing through the gears. Plus I'm investigating a pump/cooler oiling system for the trans to help cool down the oil and the gears. Similar to what is done on the differentials of race cars.

I wouldn't say no limits! I just don't like to cut corners. It's the reason why my car still isn't finished. It takes time to set money a side to pay for these parts. I don't have money flowing out of my pockets... it's the reason why I didn't buy the Porsche 911 Turbo I wanted. I didn't want to be strapped to a high car payment every month. With this project it's a pay as you go until it's finished

I'm currently working with Terry Haines on my transmission. Another reason why I haven't started reassembling the powertrain. I'm looking into the possibility of having the gears coated/baked with a cermaic/moly coating. This would provide a little more of a cushion to the torque that is going to be flowing through the gears. Plus I'm investigating a pump/cooler oiling system for the trans to help cool down the oil and the gears. Similar to what is done on the differentials of race cars.

have you thought about making a stand alone oiling system for just the turbo? your issue would be where to put it but it would take some of the strain off of the engines oil pump.

the problem is: is it worth the investment in addressing an engine design that has had quite a bit of oiling issues for various reasons for price + added complexity.

personally I would side heavily with the dry sump over seperate turbo system as its a tested design (personally I would also forgo the custom tank for tapping a beer keg in the trunk to really give it some oil cooling capacity), although while "tested", I still would only trust stress testing it on a stockish motor. My 2 cents, I think the dry setup is a pretty big deal but can't put my money where my mouth is (and again personally with the price of long blocks for our car would get a better ROI keeping stock blocks and budgeting for replacing them at least once a year than a crazy build.... sorry just the cost of 3L is so damn cheap).

So are you doing Swain for the coatings? Lately I've seen a lot of love for their crank shaft low friction coating. Also have you ever looked into any of the cryro stuff? I use to work next to one of the big players in the industry and have had some very lengthy conversations.... I don't consider their work to be snake oil.